Machine Specs

WOODTRON ADVANCED AUTO W3112AA

3000mm x 1200mm Max. Panel Size

50mm Max. Panel Thickness

12 Tool ATC & 18 Tool Gang Drill

Fully automatic nesting cell, with simultaneous loading and unloading of panels – perfect for high performance and fast production parts

MULTICAM SR2515V

2500mm x 1500mm Max. Panel Size

80mm Max. Panel Thickness

8 tool ATC

Manual and Vacuum work holding Options – perfect for precision, custom and prototype parts.

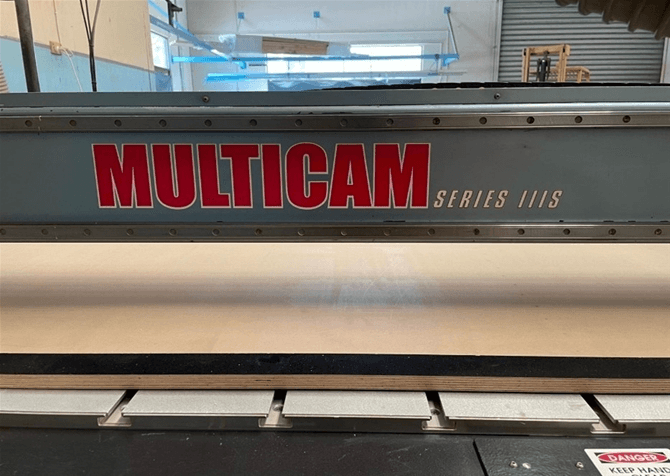

MULTICAM SERIES III-S

5400mm x 1800mm Max. Panel Size

80mm Max. Panel Thickness

8 tool ATC

Our New CNC router is built for large-scale production. Its expansive work area accommodates oversized panels, reducing downtime and increasing throughput.

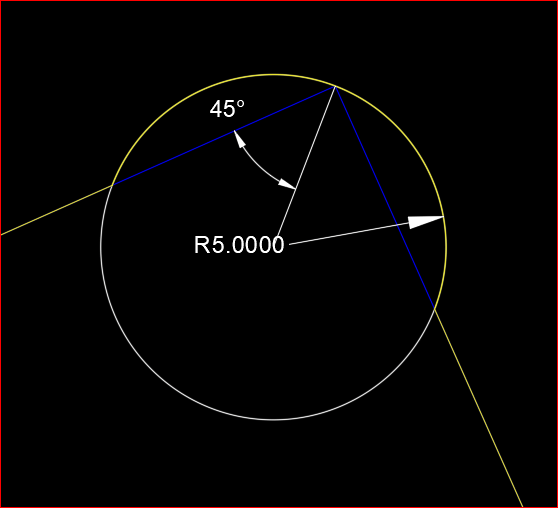

File Type & Setup

2D vector files – DWG, DXF, or AI

- 3D files – Fusion 360, OBJ, STI, STP or 3DM

If you are unable to provide a CAD design, simply issue detailed construction drawings and we can offer professional CAD design services.

FAQ’s

CNC (Computer numerical control) is the process of executing pre-programmed sequences of machine control commands. CNC machines can cut complex shapes, text and contours into almost any material

MDF

Plywood

Acrylic

High-density foam

Hardwood

Aluminum

And more

Most of our router bits are designed to cut materials under 32mm, but can go thicker. Standard thicknesses for sheet materials are 3, 6, 9, 12, 15, 18 and 25mm

CNC Machining takes a large amount of time in the initial setup and tooling stage.

One-off / small prototyping / custom material jobs are therefore may become uneconomical for some customers.

However complex parts and large quantity’s become very afordable because the cutting process becomes complete automated.

CNC-Cut can provide detailed quotes based on your exact project specifications.

If you would like to supply your own material, you can deliver it to our workshop.

Alternatively we can recommend a suitable material for your job and source it from our suppliers.

2D vector files – DWG, DXF, or AI.

3D files – Fusion 360, OBJ, STI, STP or 3DM

If you are unable to provide a CAD design, simply issue detailed construction drawings and we can offer professional CAD design services.